DRY HCL GAS GENERATOR SYSTEMS

There are three types of HCL – gas generation plants designed and supplied by us. These are the processes prevalent in the chemical process industry today. Our HCL Gas generator plants are designed and manufactured as per current international standards and codes which guarantee product durability, quality, smooth and trouble free operations.

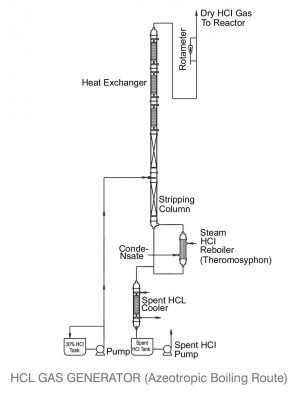

Process No : I - Azeotropic Boiling Route

30% HCL Solution is boiled thermo-symphonically in an azeotropic distillation column still where the heat energy to the re-boiler is supplied by steam. This HCL Generation plant is for continuous operation under monitored feed rate 30% HCL solution. The vapour from re-boiler strips the available gas from the feed in the column. The bottom product is 20% HCL solution which is cooled, stored for treatment & disposal.

The Salient Features of this process:

- Low capital cost

- Simple process

- Compact Design

- Low operating cost

- Pure 20% HCL as bottom Product

- No sulfuric acid handling

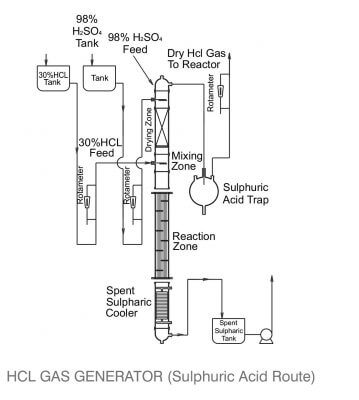

Process No : II - Sulphuric Acid Route

This HCL Generator Plant is designed to produce dry HCL-gas by the process of dehydration of 30% HCL solution with concentrated Sulfuric Acid. SA is fed from the top of the packed column as a co-current feed to 30% HCL sol. from the middle of the column. HCL gas is generated when the two acids come in contact with the bottom portion of the column. Bottom product from this plant is spent F A (70%) solution with some percentage of HCL. This again has to be cooled and stored for final treatment & disposal.

The Salient Features of this process:

- Low capital cost

- Simple process

- No drying required

- Compact design

- Effluent with HCL impurity

- Large quantity of 98% sulfuric acid handled

- High operating cost

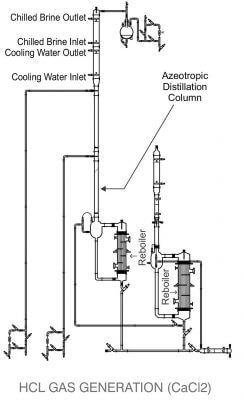

Process No : III - Calcium Chloride Route

The process produces HCL gas continuously by azeotropic distillation of 30% HCL solution along with a co-current stream of Calcium Chloride Solution. The calcium chloride breaks the azeotrope formed between HCL and water and as a result, all the HCL available in the solution is released as gas. The bottom product from the column is dilute calcium chloride solution with some HCL content. This Calcium Chloride solution is concentrated in the evaporator and recycled to the distillation column. The vapour from evaporation process consists of water and 1% (max) HCL by weight. This vapour is condensed & pH adjustment prior to discharge to the drain.

The Salient Features of this process:

- No effluent

- Zero discharge

- Lowest operation cost

- High capital cost